产品中心 / Product center

|

|

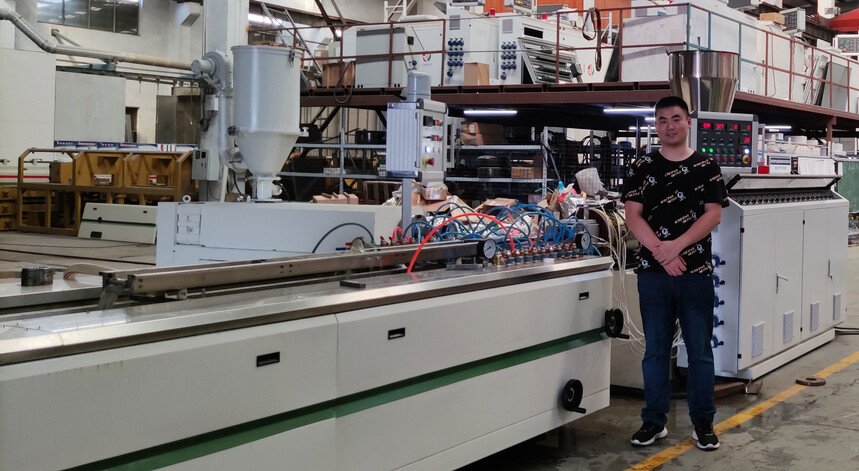

Wood Plastic Composite PVC PE WPC Decking Floor Profile Extrusion Production Line

Collect

Exterior WPC decking board making machine extrusion line

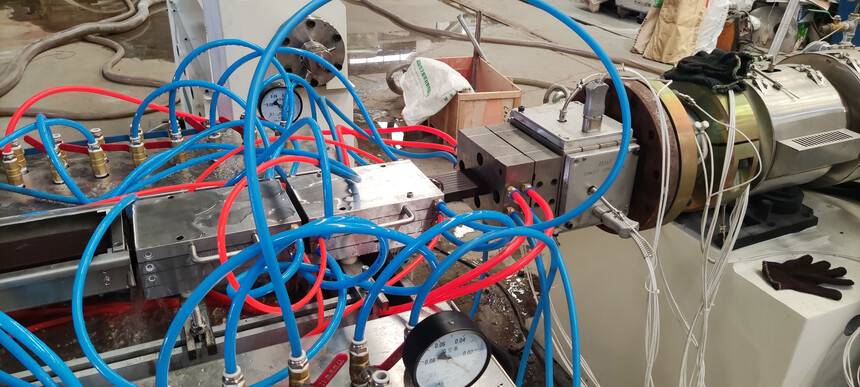

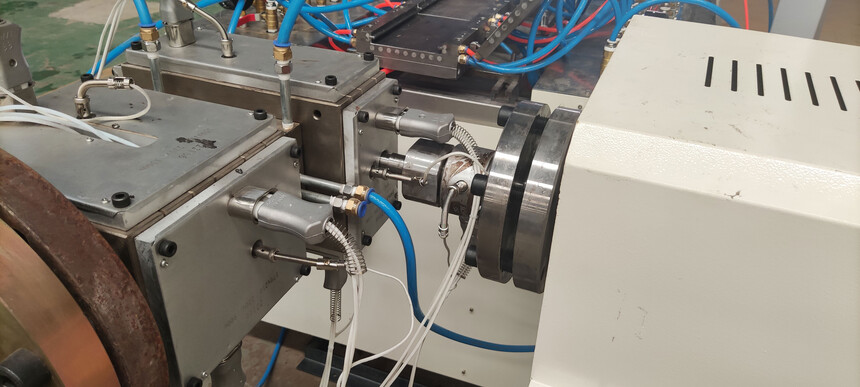

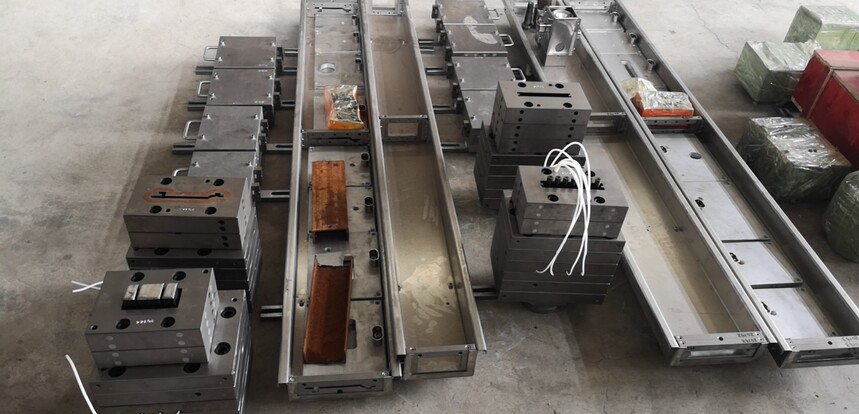

Brief introduction for WPC PE profile extrusion machine Outdoor WPC PE decking board making machine including for main parts, they are twin screw extruder, vacuum calibrator, hauling engine and cutting machine. Anxing Machinery use world famous band of motor, engine, gearbox to produce and guarantee the quality of machine. Main features for WPC PE board extrusion machine 1.High speed, double output than common WPC PE production line, greatly decrease the labour cost and electricity cost and manage cost. 2.Extruder adopts WPC PE dedicated screw, make sure best plastisizing effect 3.Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed 4.Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level 5.The caco3 filler can up to 3=5phr, formula cost is greatly reduced. 6.Equipped with infrared tracking device which can eliminate the problem of fluctuation of extrusion flow rate, further can make sure get best product 7.Lower power consumption,it can save 25-30% electrical power consumption comparing with most kind PVC ceiling production line. 8.With online hot stamping, easy operation, saving labour. Main parameter for WPC PE profile production line

For any inquiries about WPC PE production line, welcome to contact us anytime

|